Thread-rolling screws

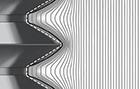

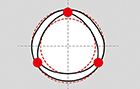

Thread-rolling screws are screws that form their mating thread themselves in a pre-drilled or cast core hole without cutting by means of special thread geometry. Thread-rolling screws therefore act as a positive-locking retainer.

These screws are used in through-holes and very often in cast core holes (aluminium or die-cast zinc).

DIN 7500

DIN 7500 is the oldest and most widely used design and defines the thread and the technical delivery conditions. However, screws such as Taptite, Duo-Taptite and Taptite 2000 are also currently very common on the market.

Features

| The requirements for the evaluation of the mechanical and functional properties of a thread-rolling screw include: | |

|---|---|

Surface hardness Edge hardness (E.H.) | DIN 7500 + DIN 267-30 for the FKL 10.9 (ISO 20898-1) |

| Core hardness | DIN 7500 + DIN 267-30 for the FKL 10.9 (ISO 20898-1) |

| Minimum fracture torque | DIN 7500 + DIN 267-30 for the FKL 10.9 (ISO 20898-1) |

| Rolling torque | DIN 7500 + DIN 267-30 for the FKL 10.9 (ISO 20898-1) |

Contact

We are there for you!

We will be pleased to advise you personally.

Contact us at 519-756-9700 or by e-mail at info@wurthindustry.ca